|

| October 22, 2013 | Volume 09 Issue 40 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Diagnosing car noises with visualizations

Hyundai helps to dramatically improve a portable sound camera it uses for buzz, squeak, and rattle studies based on LabVIEW and FPGA.

By Kang-Duck Ih, Hyundai Motor Group; and Youngkey K. Kim, SM Instruments Co., Ltd.

Consumers expect their cars to be free from audible transient noise commonly known as buzz, squeak, and rattle (BSR). These noises influence customer satisfaction studies such as the J.D. Power Initial Quality Study (IQS), in which several Hyundai vehicles have scored top ratings. Impact and friction between moving parts cause these noises.

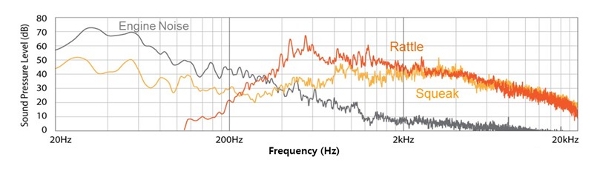

Buzz is a short, impact-induced noise with high-frequency content due to resonance. Many squeaking noises occur when a linear motion is introduced on metal contacting metal, or when rubber is forced over a metal pulley. A rattle can happen when the vehicle is in motion or when the engine is running with the vehicle stopped. A rattle can be created by the audio speakers when they generate low-frequency and high-intensity sounds. The first step in taking corrective action is to identify the source of the noise, but that can be difficult.

Acoustic beamforming involves mapping noise sources using an acoustical array. It discerns the direction from which the sound originates by the time delays that occur as the sound passes over an array of microphones such as a sound camera.

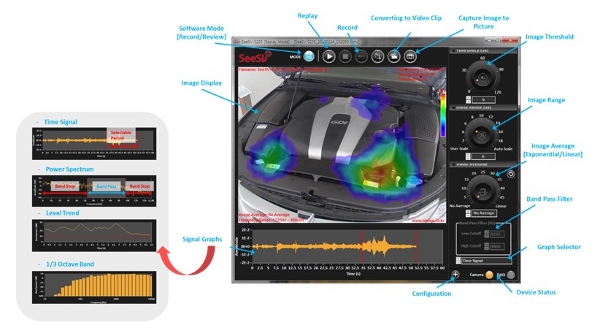

Figure 1. SeeSV Sound Camera is used to identify the effect of engine cover on the Hyundai Genesis.

Figure 2. BSR noise occurs at a higher frequency spectrum than normal engine noise.

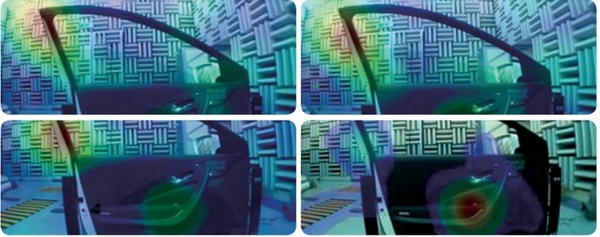

A sound camera visualizes sound in color contours similar to the way a thermal camera visualizes temperature. A microphone array, which implements a beamforming method, locates noise sources visually, making it one of the best devices to detect BSR noises. Several commercial beamforming devices convert the signals of the array into noise magnitude contours. These devices integrate cameras to overlay the contours onto the optical images, which simplifies noise source location. The devices can take several noise images per second to provide noise videos. Normally, the noise image and video quality increase in higher frequency ranges, since the performance is inversely proportional to the wavelength of the noise.

Figure 3. Noise sources are detected on a vehicle door and window.

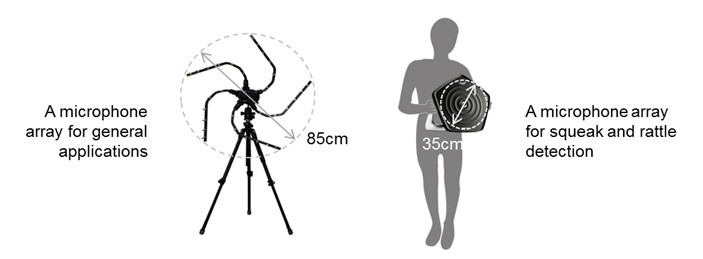

Identifying noise sources poses challenges for some devices. First, the devices need to have fast response times to capture transient noises. Most BSR noises occur irregularly and quickly. Sometimes the noises happen in a few milliseconds and then disappear. Second, for this application we needed a lightweight device that was small enough for portable use in the interior of a passenger vehicle where most BSR noises occur or are noticed. Since the size of the array is proportional to the image resolution, especially at low-frequency ranges, it has not been easy to make small beamforming devices. We optimized this portable beamformer for BSR noise, which falls mostly between 300 Hz and 8 kHz, where the higher frequency ranges powered the use of a smaller array, making it suitable for mobile use.

The first systems we developed for noise source identification used analog microphones with 30-channel to 48-channel spiral arrays up to 85 cm (34 in.) in diameter. We acquired data using the National Instruments (NI) 9234 dynamic signal acquisition (DSA) module in an NI CompactDAQ system for the 30-channel version, and we used the NI PXIe-4497 DSA module for the 48-channel version. We developed a sound camera application in LabVIEW with the NI Sound and Vibration Measurement Suite that included sound-quality measurements for real-time display. The larger array size made it suitable for both BSR noise source identification as well as noise, vibration, and harshness (NVH) identification down to 50 Hz. The sound camera has been used in a variety of applications including visualizing pass-by tire noise and door panel noise due to speakers.

Figure 4. A larger microphone array is used for NVH applications versus a BSR array.

Because signal processing devices are rapidly improving, we redesigned our beamforming system to be light enough for BSR noise detection in tight spaces to meet the needs of Hyundai by using Microelectromechanical systems (MEMS) microphones and field-programmable gate array (FPGA technology. The performance of MEMS microphones has advanced through their use in consumer electronics like cell phones. They are now highly reliable and affordable and feature flat responses in the frequency range of a human voice between 300 Hz to 8 kHz, the primary frequencies of interest in BSR noise. A digital MEMS microphone integrates an acoustic transducer, a preamplifier, and a sigma-delta converter into a single chip. Since the chip converts the analog signal into the digital pulse train, we eliminated much of the instrumentation to reduce the size and weight of the system while maintaining high-level performance.

Figure 5. Ergonomically designed handles enhance the ease of use of the SeeSV Sound Camera.

We ported the application using the LabVIEW FPGA Module to convert the computationally intensive beamforming algorithms to run on an NI Single-Board RIO FPGA, which further helped with size, cost, and portability. This also made it possible to integrate signal conditioning, data acquisition, filtering, and beamforming into a single chip to connect the acquisition hardware directly with the processing unit in the FPGA, which minimized latency. The FPGA could perform hundreds of operations every cycle, surpassing the computational performance of the PC by massively parallel operations.

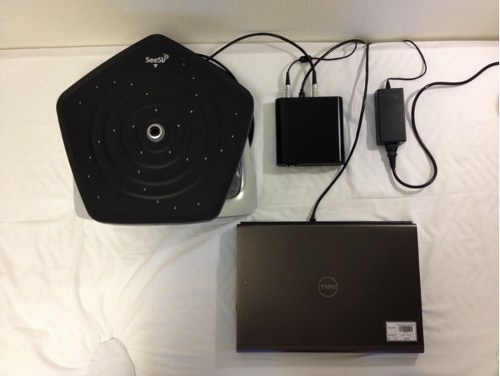

Figure 6. The system weighs less than 2 kg (5 lb).

The system weighed less than 2 kg (5 lb) for improved portability and durability. We designed a single, solid-body fixture for the microphone array and a camera with three handles on the back to help with stable one-handed or two-handed operation. We mounted all the sensors in the main body with integrated cabling, which reduced size by 60 percent and reduced weight by 70 percent versus the previous system.

Video: Engine Test

Video: Dashboard Test

Users can take advantage of the system's small size and weight to interactively explore various noise sources found inside and outside a vehicle, even in narrow spaces. The integrated design reduces set-up time significantly. With its high image-per-second update rate, the system proves very effective in capturing and displaying transient noise and is being used in tests on several new luxury models such as the Hyundai Genesis in which BSR noise is not acceptable.

Learn more about SM Instruments' SeeSV Sound Camera here.

Source: National Instruments

Published October 2013

Rate this article

View our terms of use and privacy policy